Edge Welded Bellows – DN25

P.O.A

- CF Flanges

- KF Flanges

- Weld

TECHNICAL SPECS – CLICK HERE

Edge Welded Bellows – DN25

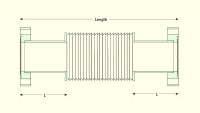

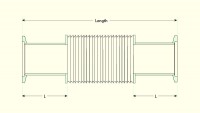

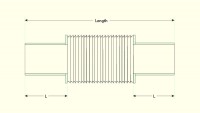

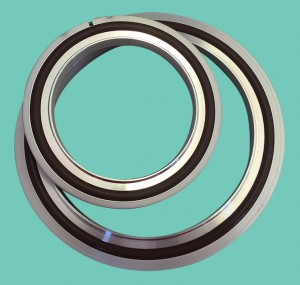

LewVac edge welded bellows are more suited to applications that require greater flexibility, particularly axial compression and extension. Edge welded bellows are manufactured from a series of formed metal diaphragms welded together. Each diaphragm contributes to the overall extension / compression. More discs means greater extension attainable and also the greater the lateral offset achievable.

Features:

• 316L stainless steel as standard for lower cycle requirement applications (typically 10,000 cycles).

• AM350 stainless steel also available for long lifetime (typically 500,000 cycles).

• Titanium, Inconel® or Hastelloy® available on request.

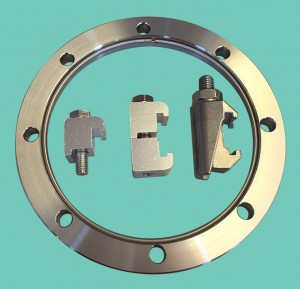

• 304 stainless steel end plates, tubes and flanges as standard.

• Custom sizes and designs available on request.

• One fixed, one rotatable flange on CF assemblies.

Specifications:

Temperature range:

– 316L : operating at Ambient, baking up to 80˚C.

– Higher temperature versions are available, please call us to discuss.

Materials:

– Flanges : 304(L) stainless steel as standard.

– Bellows : 316L stainless steel as standard.

| Product Code | Flange | Through bore | Max. bellow OD | Stroke | Compressed length | Extended length | L | Price | Quantity | PDF & STP | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| EWB25CF-10 | DN25CF | 26.0 | 46 | 10 | 60.7 | 70.7 | 29 | P.O.A | |||

| EWB25CF-20 | DN25CF | 26.0 | 46 | 20 | 63.4 | 83.4 | 29 | P.O.A | |||

| EWB25CF-30 | DN25CF | 26.0 | 46 | 30 | 66.1 | 96.1 | 29 | P.O.A | |||

| EWB25CF-40 | DN25CF | 26.0 | 46 | 40 | 68.8 | 108.8 | 29 | P.O.A | |||

| EWB25CF-50 | DN25CF | 26.0 | 46 | 50 | 71.5 | 121.5 | 29 | P.O.A | |||

| EWB25CF-60 | DN25CF | 26.0 | 46 | 60 | 74.2 | 134.2 | 29 | P.O.A | |||

| EWB25CF-70 | DN25CF | 26.0 | 46 | 70 | 76.9 | 146.9 | 29 | P.O.A | |||

| EWB25CF-80 | DN25CF | 26.0 | 46 | 80 | 79.6 | 159.6 | 29 | P.O.A | |||

| EWB25KF-10 | DN25KF | 26.0 | 46 | 10 | 30.7 | 40.7 | 14 | P.O.A | |||

| EWB25KF-20 | DN25KF | 26.0 | 46 | 20 | 33.4 | 53.4 | 14 | P.O.A | |||

| EWB25KF-30 | DN25KF | 26.0 | 46 | 30 | 36.1 | 66.1 | 14 | P.O.A | |||

| EWB25KF-40 | DN25KF | 26.0 | 46 | 40 | 38.8 | 78.8 | 14 | P.O.A | |||

| EWB25KF-50 | DN25KF | 26.0 | 46 | 50 | 41.5 | 91.5 | 14 | P.O.A | |||

| EWB25KF-60 | DN25CF | 26.0 | 46 | 60 | 44.2 | 104.2 | 29 | P.O.A | |||

| EWB25KF-70 | DN25KF | 26.0 | 46 | 70 | 46.9 | 116.9 | 14 | P.O.A | |||

| EWB25KF-80 | DN25CF | 26.0 | 46 | 80 | 49.6 | 129.6 | 14 | P.O.A | |||

| EWB25W-10 | Weld | 26.0 | 46 | 10 | 82.7 | 92.7 | 40 | P.O.A | |||

| EWB25W-20 | Weld | 26.0 | 46 | 20 | 85.4 | 105.4 | 40 | P.O.A | |||

| EWB25W-30 | Weld | 26.0 | 46 | 30 | 88.1 | 118.1 | 40 | P.O.A | |||

| EWB25W-40 | Weld | 26.0 | 46 | 40 | 90.8 | 130.8 | 40 | P.O.A | |||

| EWB25W-50 | Weld | 26.0 | 46 | 50 | 93.5 | 143.5 | 40 | P.O.A | |||

| EWB25W-60 | Weld | 26.0 | 46 | 60 | 96.2 | 156.2 | 40 | P.O.A | |||

| EWB25W-70 | Weld | 26.0 | 46 | 70 | 98.9 | 168.9 | 40 | P.O.A | |||

| EWB25W-80 | Weld | 26.0 | 46 | 80 | 101.6 | 181.6 | 40 | P.O.A |